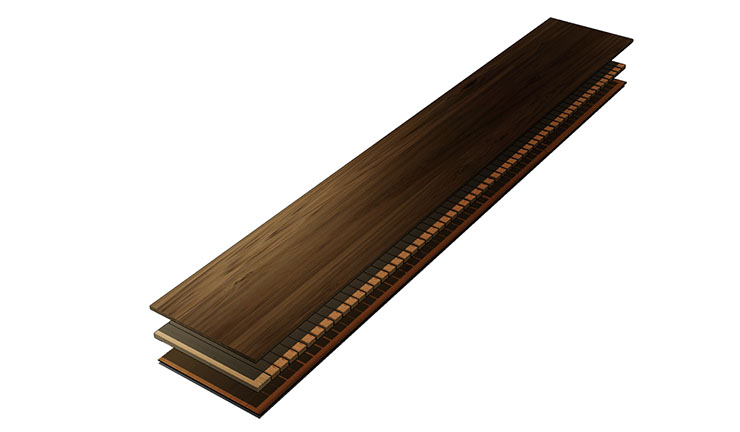

Lamella refers to the top layer of engineered wood flooring or other wood-based composite products. It is typically a thin veneer of solid wood that is bonded to a stable core material, such as plywood, HDF (high-density fiberboard), or softwood layers. The lamella layer determines the appearance, texture, and durability of the final product while allowing for greater stability and efficient use of natural wood resources.

Quality and Characteristics

1. Appearance

- The visual appeal of lamella depends on the species of wood used (e.g., Oak, Walnut, Ash, or Teak).

- It maintains the natural grain, texture, and color of real wood, providing an authentic look.

- Can be brushed, stained, or finished in various ways to enhance durability and aesthetics.

Durability and Strength

- Since the lamella is a thin layer of real hardwood, its durability depends on the thickness (typically between 2mm and 6mm).

- When combined with a strong core, it creates a stable, warp-resistant surface that is less affected by moisture and temperature changes than solid wood.

- High-quality lamella can be sanded and refinished, extending the lifespan of engineered wood flooring.

Workability

- Lamella wood is easier to install than solid hardwood due to its engineered structure.

- It can be glued or pressed onto various core materials, offering flexibility in manufacturing.

- Works well with modern flooring techniques, such as tongue-and-groove or click-lock systems.

Common Uses

- Engineered wood flooring for residential and commercial spaces

- Wood panels and veneers for furniture and interior decor

- Doors and cabinetry for a premium wood finish

- Acoustic panels and wall cladding in luxury interiors